- Nouveau

Garanties sécurité

Garanties sécurité

(à modifier dans le module "Réassurance")

Politique de livraison

Politique de livraison

(à modifier dans le module "Réassurance")

Politique retours

Politique retours

(à modifier dans le module "Réassurance")

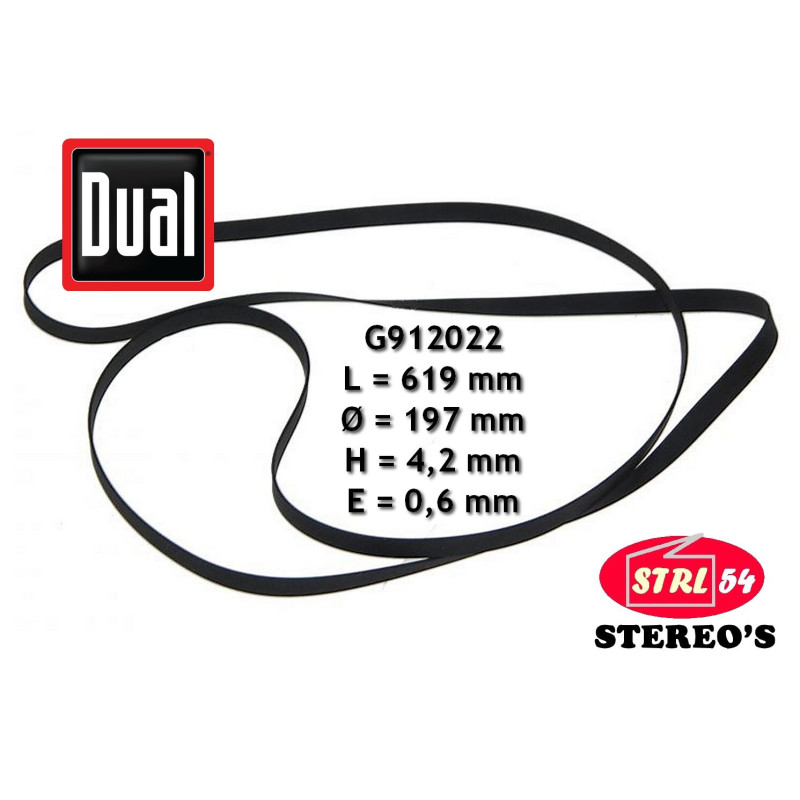

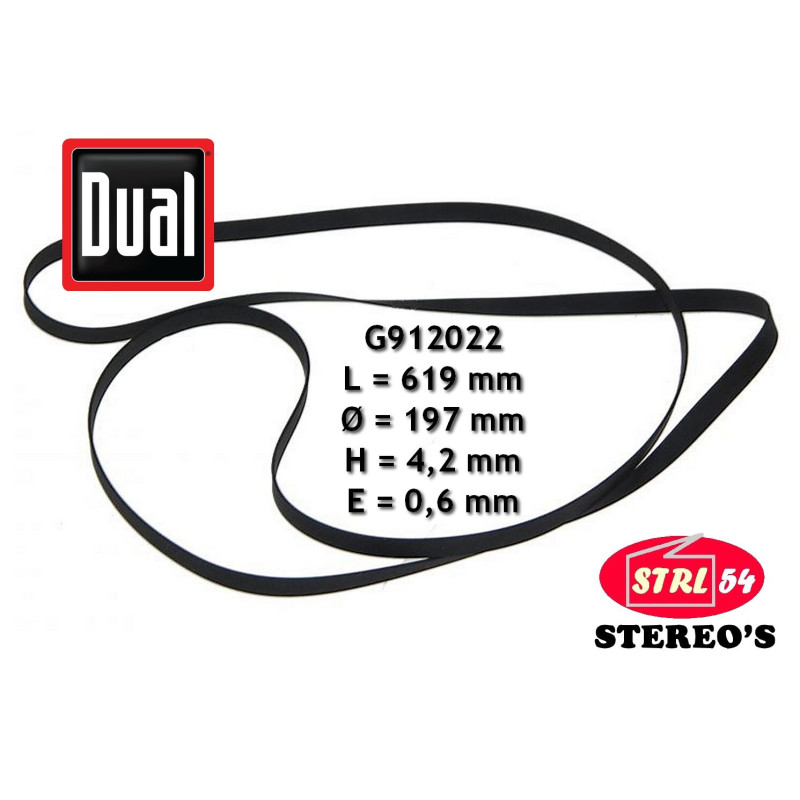

IMPORTANT :

This belt will not suit all models of DUAL Vintage dual turntables, as there are, but will be able to go very well for models of other brands, for example a BST PR 70/2 (has been tested)

To find the adequate training belt for a conventional disks turntable , you can measure the diameter of the sub-platform, as well as the distance between the edge of the sub-platform and the axis of the engine pulley.

If the motor pulley axis is only distant from a few centimeters from the edge of the sub-platform (the most common case), a method is to choose a belt whose inner diameter is equal or a little lower than that of the sub-platform.

However, it is also necessary to see what is the ideal height for the belt, because it will have to pass between the fork moving for the change of speeds (33/45 etc) without rubbing, as well as the thickness of the rubber (elastomer), as it will influence the tension. Too relaxed a belt can skate and not be able to change the speed level on the engine axis, and conversely a strap too tense can slow down, or even block training.

IMPORTANT :

This Belt will not fit All Vintage DUAL Turnables, as there are so many of them of them, but it may be followed for other brands, for examples a bst pr 70/2 (has been tested).

To find the right Drive Belt for a Classic Turnable, you can measure the Diameter of the Sub-Platter, as well as the Distance Between the Edge of the Sub-Platter and the Motor Pulley Shaft.

If the Motor Pulley Axis is only a few Centimetres from the Edge of the Sub-Platter (The Most Common Case), One Method is to choose a Belt Whose Inside Diameter is Equal to or Slightly Smaller that of the Sub-Platter.

However, you also need to consider the ideal height for the Belt, as it will have to pass between the fork moving for the gear change (33/45 etc) without rubbing, as well as the thickness of the rubber (elastomer), as this will influence the tension. A Belt that is too much slack could slip and not be able to change gear on the motor shaft, and on the opposite, a belt that is too tightned could sweet down or even block the drive.

Fiche technique